Video

Soft and Highly Flexible

TPU’s rubber-like texture and flexibility make it ideal for printing models like insoles, phone cases, and wristbands. Drying the filament beforehand improves print quality [1].

Outstanding Toughness

Anycubic TPU delivers unparalleled toughness and tear resistance, outperforming conventional materials.

Excelent Weather Resistance

Anycubic TPU offers excellent wear and oil

resistance, bright colors, clump-free

performance, and long-lasting durability.

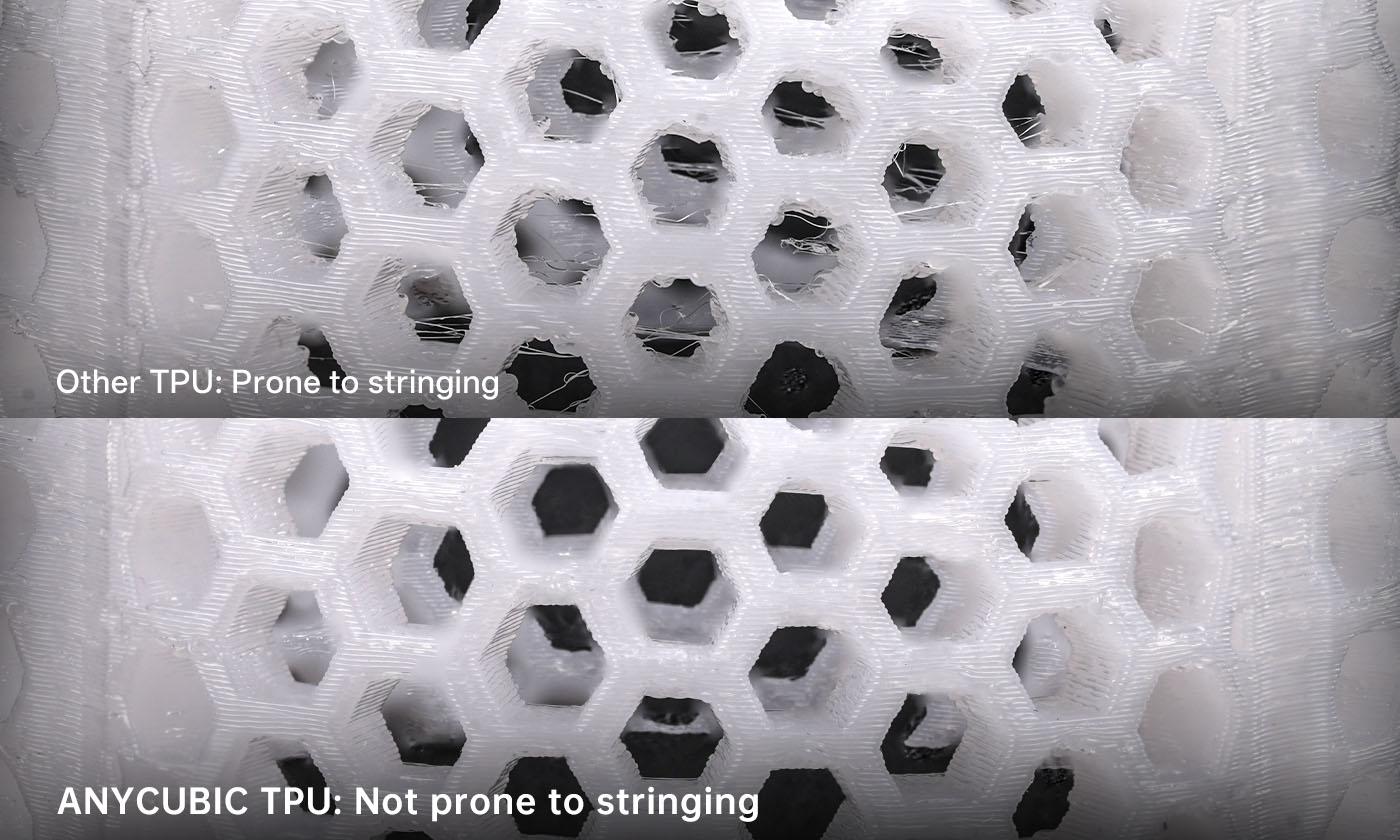

Optimized Settings for Anycubic TPU

Pre-configured TPU settings in the slicer minimize stringing and ensure excellent print results.